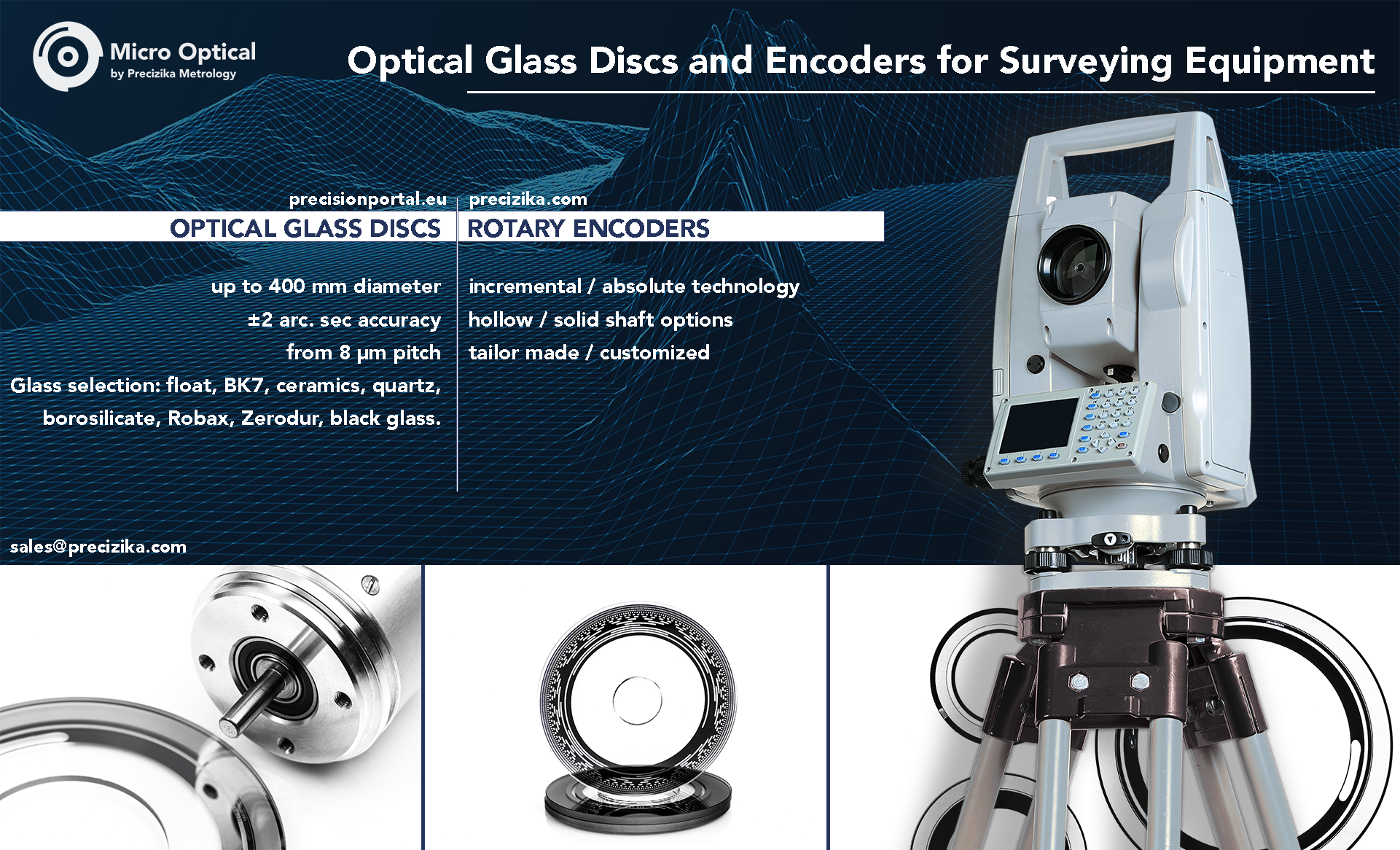

Optical Glass Discs and Encoders for Surveying Equipment

Encoder glass discs are a critical component in modern surveying equipment such as total stations and theodolites. These discs play a crucial role in measuring angles and distances with high accuracy, which is essential for mapping and construction projects.

An encoder glass disc is a circular glass plate with a series of parallel lines etched onto it. These lines form a precise pattern that is read by a photoelectric sensor as the disc rotates. The sensor converts the pattern into electrical signals that are then processed by the equipment’s microprocessor to determine angle and distance measurements.

The high accuracy of encoder glass discs is due to the precision with which the lines are etched onto the glass. The etching process creates lines that are perfectly straight and evenly spaced, with very small variations in their width and depth. This level of precision ensures that the photoelectric sensor can read the pattern with minimal error, resulting in highly accurate measurements.

Another benefit of encoder glass discs is their durability. The glass used in these discs is highly resistant to scratches and other forms of wear and tear, ensuring that the disc remains accurate even after prolonged use in harsh field conditions.

In addition to their accuracy and durability, encoder glass discs also offer flexibility in their design. Different patterns can be etched onto the glass to provide different levels of resolution and accuracy, depending on the specific needs of the application. This allows surveying equipment manufacturers to customize the discs to meet the requirements of different projects and customers.

One potential downside of encoder glass discs is their susceptibility to dirt and debris. If the glass becomes dirty or contaminated, it can interfere with the photoelectric sensor’s ability to read the pattern accurately, resulting in measurement errors. To mitigate this risk, surveying equipment manufacturers often include features such as air purging and protective covers to keep the discs clean and free from debris.

Overall, encoder glass discs are a critical component in modern surveying equipment, providing highly accurate angle and distance measurements with durability and flexibility. As technology continues to advance, it is likely that these discs will continue to play a vital role in the field of surveying and construction.

Already for 60 years our company is giving our customers competitive advantage by providing state of the art customer-specific micro-optical solutions, glass discs is one of our strengths. Our process flexibility allow us to make orders from small to large quantities for any specific customer request. Depending on selected glass, discs are available in up to 400 mm diameters and a variety of pattern specifications depending on the requirements. We have supplied glass discs to different industries including medical equipment, factory automation, radars, encoders, military and defense, etc. If any of this seems interesting, please do not hesitate to get in contact with us or just order a free sample!